PBA Systems June 2013 Newsletter

20 Jun 2013

Hits: 1061

In this Edition:

Case Studies

-

-

- High Speed & High Precision LCD Panel Assembly Machine

- Automated Stamping Machine

- Muli-workstations

-

Case Studies

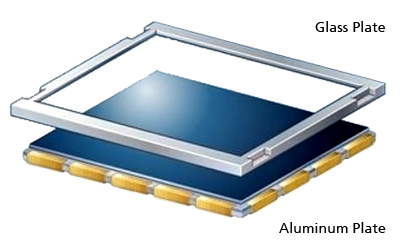

High Speed & High Precision LCD Panel Assembly Machine

This machine is used for the assembly of LCD panels. The machine picks up the glass plate, removes the protective film and then combines it with the aluminum plate.

There are two axis in this machine – X & Y. The X-axis is 2m-long with two carriages.

To meet the high speed and high precision motion requirements, the customer has decided to use PBA Systems DX B series Ironless linear motor.

| Y | X1 | X2 | |

| Stroke (mm) | 200 | 1200 | 800 |

| PBA Systems Motor Model | DX30B-C2S | DX30B-C4S | DX30B-C3S |

| Encoder | RH200, 0.5 um | RH200, 0.5 um | RH200, 0.5 um |

| PBA Systems MaxTune Servo Drive | MT-4/12-AP1 | MT-6/25-AP1 | MT-6/25-AP1 |

The main advantages of the PBA Systems DX B series Ironless linear motor are:

- high precision motion

- high speed and smooth motion

- high continuous force

- cogging-free motion

- low setting time

- short lead time

- speed up to 1.5m/sec, acceleration up to 2G

The DX B linear motors are powered by using PBA Systems MaxTune Servo Drive. The MaxTune servo drive comes with high current loop bandwidth (up to 4.5 kHz) and advanced auto-tune control functions to help reduce tracking errors and settling time. The MaxTune Servo Drive also runs on an anti-vibration algorithm that eliminates any mechanical resonance.

Automated Stamping Machine

This machine is used for metal plate stamping. The original system consists of a standalone industrial stamping machine which was bought off-the-shelf. The plates had to be placed and removed manually.

To reduce overhead costs, the customer developed an automatic plate replacement system using PBA Systems DX B Ironless Linear Motor coupled with PBA Systems MaxTune Servo Drive. The Aurotek MC8841P motion control card was used to coordinate the motion of the clamps and the motors.

The most important requirements of this machine are high acceleration, high speed and high repeatability. This ensures that the stamping point is always precisely positioned and the UPH is higher than manual feeding.

PBA Systems has helped the customer achieve a cost-effective, high quality and efficient manufacturing line with high throughput.

| Earlier Configuration | Current Configuration |

|

|

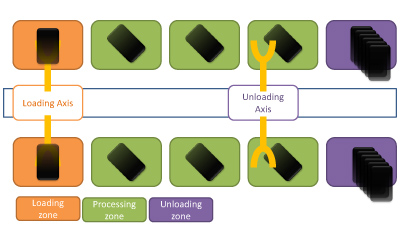

Multi-workstations Loading/Unloading System

Industries nowadays look to increasing workstations to enhance production capacity, especially if time-consuming processes are involved.

Workstations can be arranged in a circle or a straight line. The circular arrangement tends to waste space whereas the straight line arrangement requires a long axis.

In our particular setup (see diagram), the customer uses two independent carriages on the same axis to increase the loading/unloading speed and productivity, while also saving space.

PBA Systems IX Iron Core Linear Motors was used in place of the old servo motor and timing belt. This upgraded linear motor system allows movement speed of up to 4 m/s and two carriages in the same axis.

| Earlier Configuration | Current Configuration |

|

|

For more information on any of the products featured above, please contact:

PBA Systems Pte Ltd

2, Woodlands Sector 1, Woodlands Spectrum 1, #03-23, Singapore 738068

Tel +65 6576 6767 | Fax +65 6576 6768 | Email [email protected] | Website www.pbasystems.com.sg

Disclaimer: Every care has been taken to ensure the correctness of the information contained in this newsletter but no liability can be accepted for any errors or omissions. Copyright reserved. This newsletter or parts thereof may not be reproduced without PBA Systems’ permission.