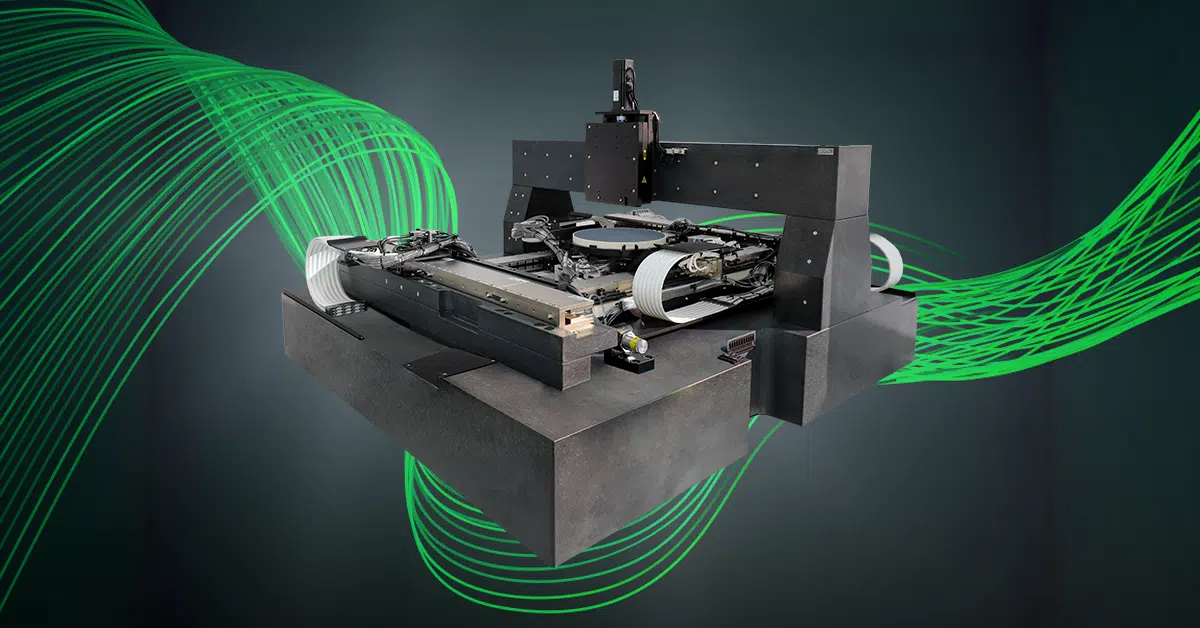

Latest Product Launch: The next-gen PABG2000 Co-Planar XYZ Theta Air Bearing Gantry

2 Dec 2024

Hits: 1987

The next-gen precision motion stage with nano grade cutting-edge air bearing technology & thermal expansion resistant design.

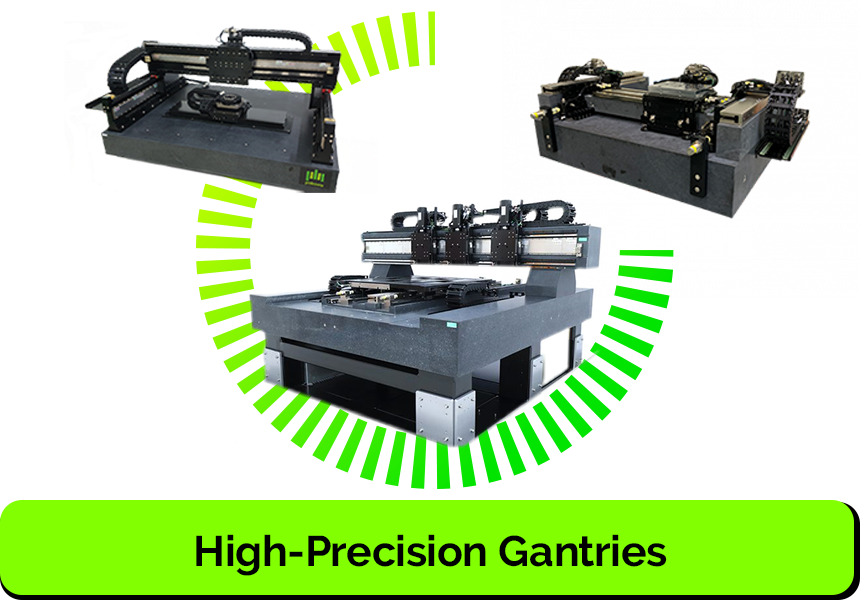

Bringing you our very latest, cutting-edge ultra-precision gantry solution – PABG2000 Co-Planar XYZ Theta Air Bearing Gantry.

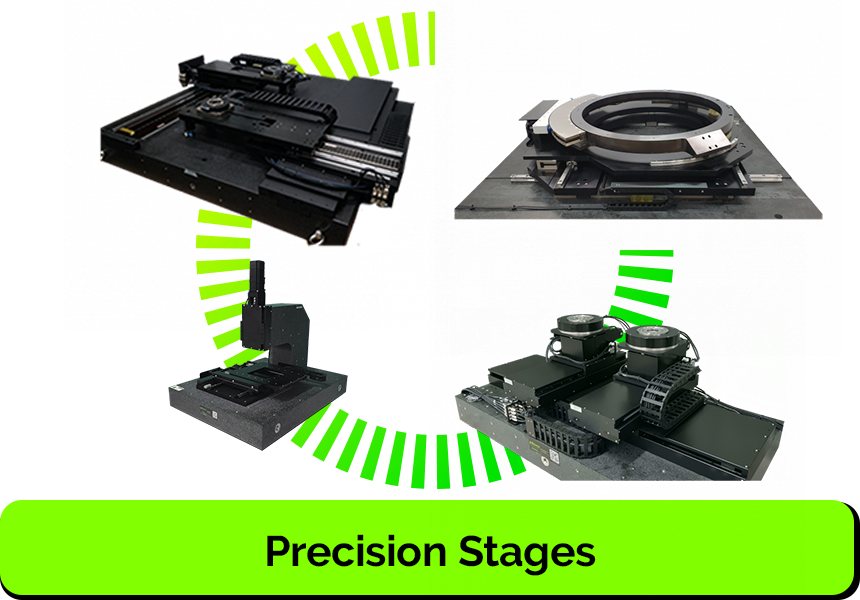

The new generation air bearing stage by PBA, PABG2000 is designed specifically for applications that require reliable ultra-smooth motion and supreme high accuracy. The ceramic design on the critical part of the stage minimises the loss of accuracy due to thermal expansion during the process. Utilising a frictionless air bearing design, this ensures ultra-precise movements with sub-micron accuracy.

The zero contact feature results in less wear and tear of mechanical parts and reduces the risk of performance degradation over time, translating to longer lifespans and lower maintenance costs. A complete stage solution offering ease of integration, the PABG2000 also boasts low velocity ripple and exceptional motion performance with high accuracy and repeatability. With lower particle generation, it is ideal for cleanroom environment – for applications in the semiconductor industry such as wafer-scribing, wafer dicing, inspection and laser-cutting for Printed Circuit Boards and microchips, as well as across industries such as MedTech, optics, and other manufacturing processes where the environment would need to be relatively dust-free, particularly if high-precision cuts which are free from defects and contamination are imperative.

The air bearing stage also features pneumatic air systems which are equipped with precise flow and pressure control, allowing for fine adjustments. Powered by unique multi-axis Servo Processor technology, PBA offers advanced gantry control algorithms that simplify the configuration and tuning process of gantry stages and enhance their accuracy, throughput, and stability.

Product Benefits:

- – Nano grade accuracy of precision motion

- – Low velocity ripple

- – Low thermal expansion

- – High accuracy and repeatability

- – Zero contact between mechanical parts reduces the risk of performance degradation over time due to wear & tear

- – Less particle generation

- – Complete solution easy for integration

Product Features:

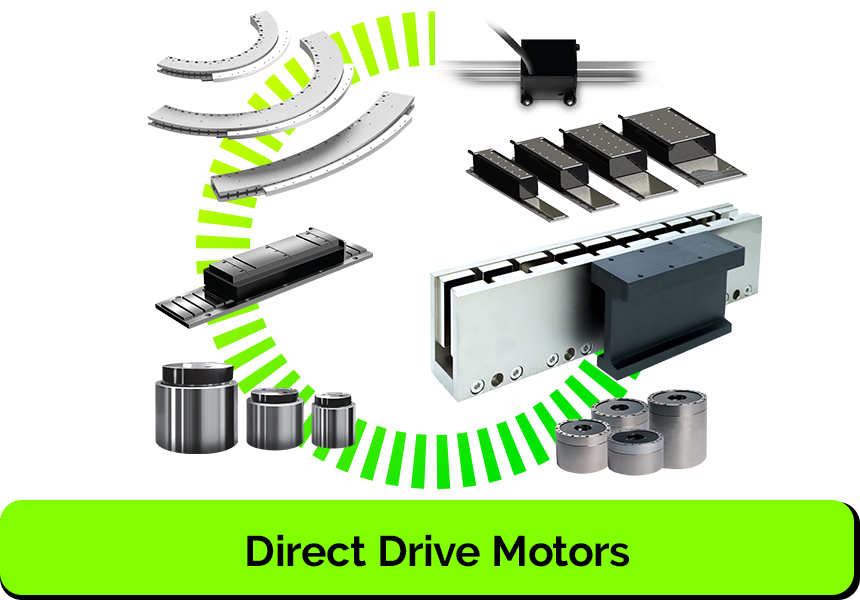

- – Powered by PBA Direct drive ironless linear motor technology

- – Vacuum preload orifice air bearing technology

- – Outstanding straightness and flatness

- – Controllable Thermal Expansion with different material combination.

- – Designed according to cleanroom environment usage

Applications:

- – Semiconductors, wafer scribing application

- – Laser cutting

- – Wafer inspection

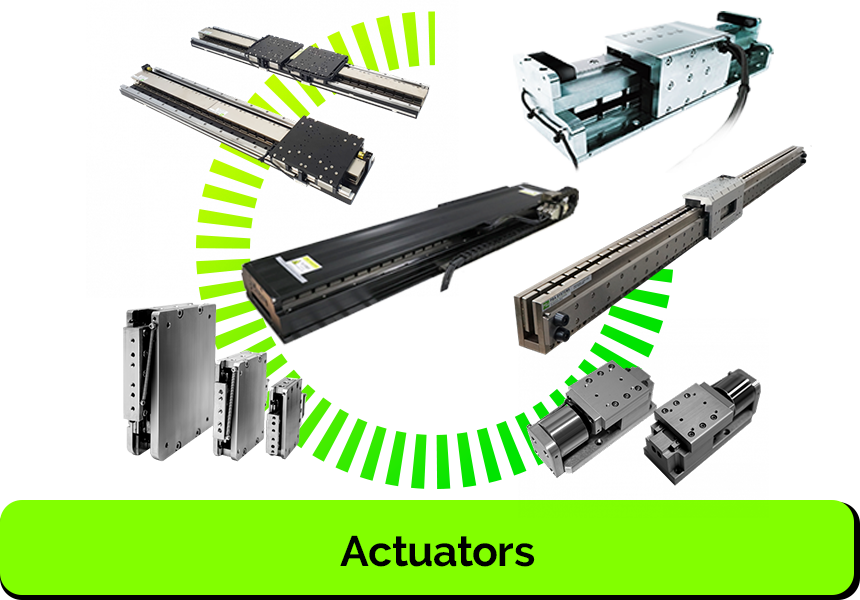

PBA Systems is an ISO-certified company and a member of the PBA Group. We are direct drive motion solutions expert for automation. We provide component, motor, to systems integration, and custom design services. Our advanced, High Precision Direct Drive Motor Technology improves the positioning, torque control, and efficiency of robotics systems, which are crucial in automation manufacturing. PBA Group specialises in proprietary robotic automation technologies. Headquartered in Singapore; with advanced manufacturing and technology centres in Taiwan, Japan, Korea, Malaysia, Thailand and China; we have the capabilities of providing customised, swift motion solutions for global customers and system partners.

For more information:

Sales Contacts: [email protected]