PBA SYSTEMS SUSTAINS EFFORTS IN EUROPE TO SHOWCASE CUTTING-EDGE MOTION SOLUTIONS AT THE 23RD PRECISION FAIR

30 Oct 2024

Hits: 2609

Following recent Motek trade fair appearance in October in Stuttgart, high-tech precision motion solutions company concludes a series of displays for its capabilities and motion expertise in manufacturing automation with exhibition in Netherlands, its European home base.

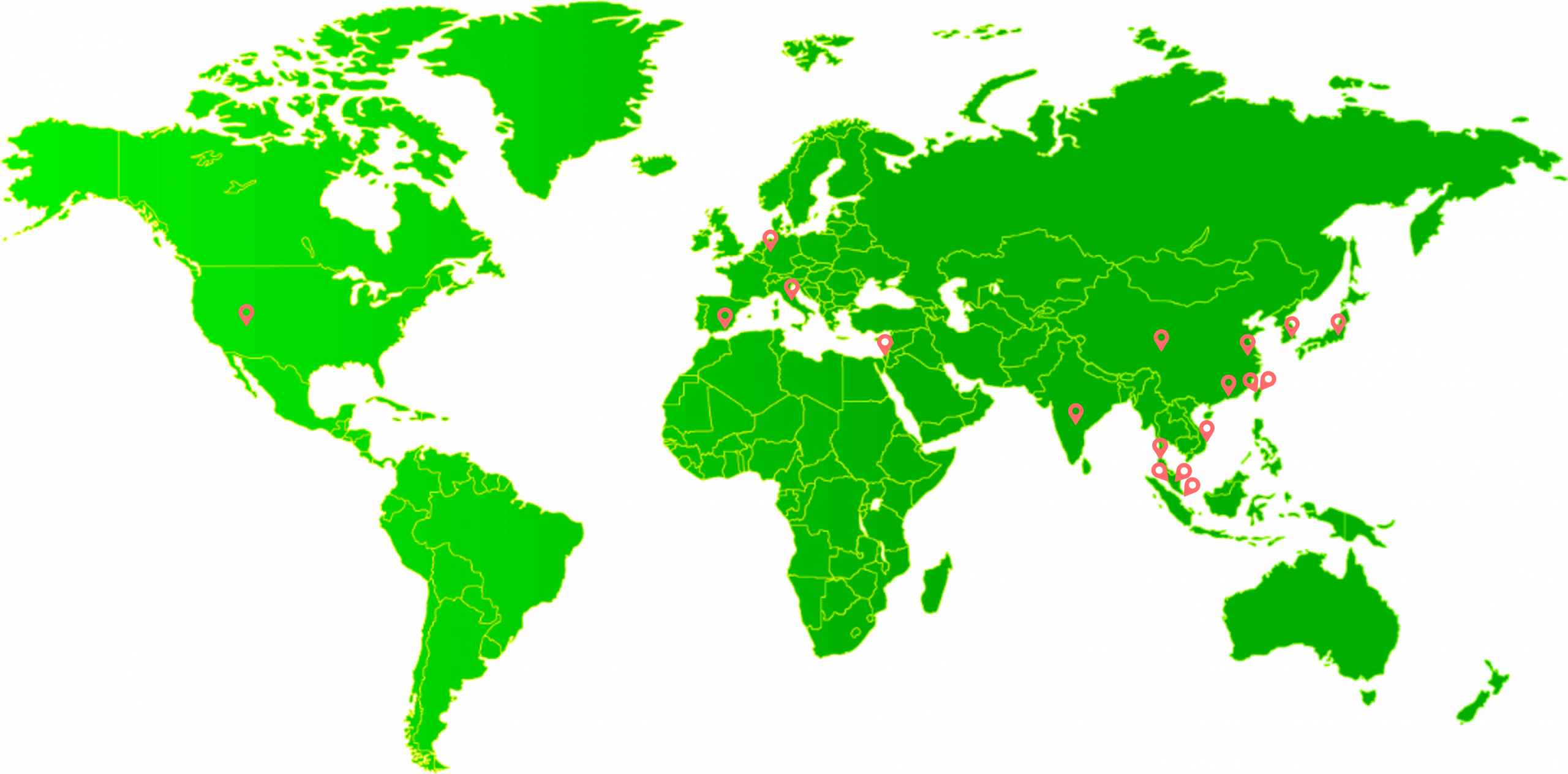

s-Hertogenbosch, Netherlands, 30 October 2024 – PBA Systems will bring the company’s latest showcase of its high-tech, innovative direct drive products and motion solutions at the upcoming 23rd Precision Fair (Precisiebeurs 2024) to be held on 13 and 14 November 2024. Renowned for its leading high-precision motion solutions, the company which is founded and headquartered in Singapore, is looking at the Precision Fair to successfully conclude its series of tradeshows in Europe, having made inroads by launching itself to the market of OEMS and system builders to revolutionise the European automation landscape since the beginning of the year.

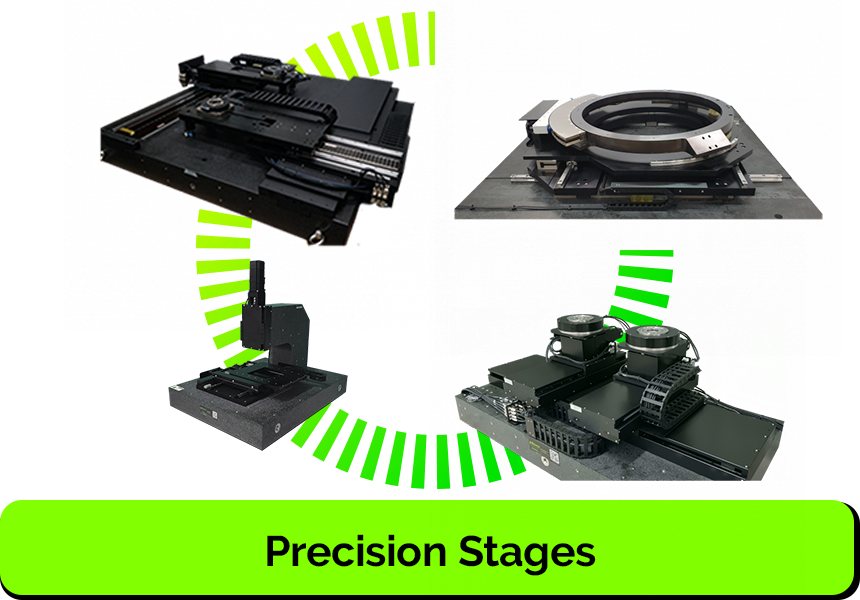

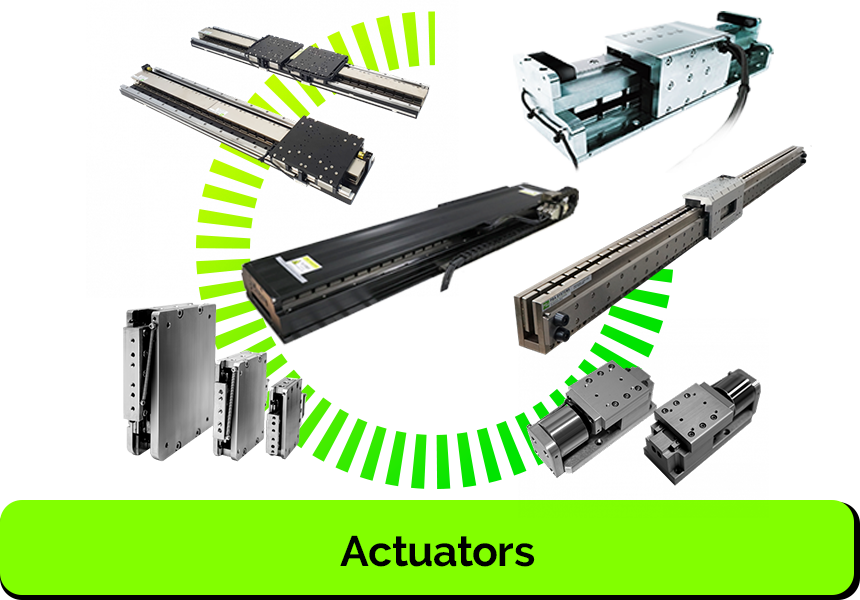

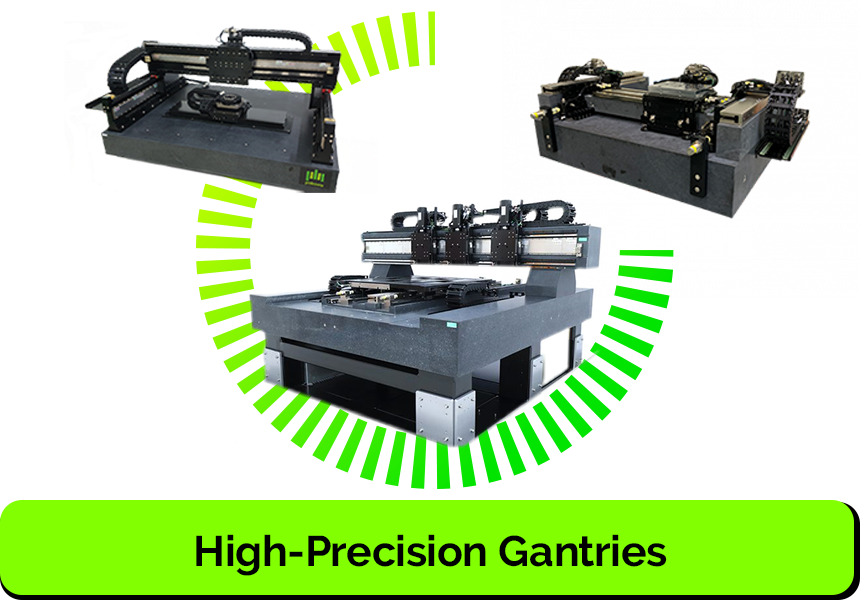

For this last push in Europe for 2024, PBA is looking to continue to connect with European manufacturers who are looking for experts in motion in their automation processes, this time with a focus on the Netherlands following a successful show in Germany. PBA Europe’s experienced technical expert consultants will again be on hand to provide detailed insights on PBA’s capabilities in design, build and manufacture of direct drive motors, actuators, modules, as well as its core competence in precision stages & gantries with customised specifications; notable for being critical solutions for industrial automation processes with high-precision as well as ultra-precision (nano grade) applications.

In line with its core business and technology focus, PBA will feature a select line-up of machinery exhibits aimed at systems builders and Original Equipment Manufacturers (OEMs) in the semiconductor industry; in growth areas of Advanced Packaging, Automated Optical Inspection (AOI), and related applications such as wafer processing; as well as other manufacturing industries where high-precision motion control for automation is in demand, such as Photonics, and Electric Vehicles (EV) industries.

The company invites all systems partners and machine builders looking for cutting-edge solutions to explore its full suite of high-tech precision motion solutions and products to Precision Fair. Scheduled discussions and personalised demonstrations of PBA’s best-in-class, innovative motion solutions will be made available for any representatives of European companies who are keen to learn how PBA’s solutions can support their specific automation requirements and enhance the efficiency, precision and overall productivity of their processes.

Visitors to PBA’s booth at Precision Fair, held at Brabanthallen ‘s-Hertogenbosch (Hall 1, Booth no: Stand 376), can register at https://precisiebeurs.nl/nl/aanmelden/. The show dates and hours are 13-14 November (Wednesday & Thursday): 1000-1700hrs.

Highlights of PBA @ Precisiebeurs:

Key Exhibits – Star Products

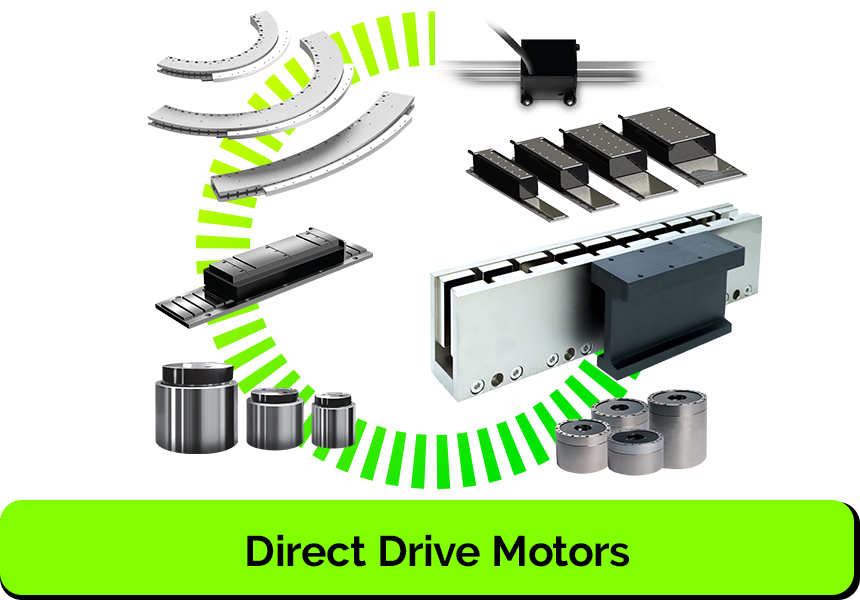

At the core of PBA’s motion solutions, powered by direct drive technology, is its proprietary range of motors. The line-up boasts a comprehensive range of ironcore, ironless, rotary and arc motor technologies offering unparalleled force, high speed, high precision and versatility for a wide range of applications. The motors deliver the power and accuracy required to elevate any automation system.

A vertical motion actuator built with a space-efficient design ideal for Automated Optical Inspection (AOI) systems, allowing for ease of integration into a multi-axis motion system. PZA-H provides minimal friction, and offers high-precision positioning accuracy, repeatability, speed and reliability. While compact in size, it has remarkable dynamic abilities and high payload capacity up to 20Kg, bolstered by the special feature of dual pneumatic counterbalances for power outage safety control against damage. PZA-H is a superior vertical motion control solution for applications such as AOI and Semiconductor inspection & quality control. The PZA series also includes the advanced-level PZA-U Ultra-Precision Z-axis actuator which boasts an impressive 75nm vertical motion repeatability for nano-Level applications.

The Multiple Z-axis module is a proprietary pick-and-place module designed for efficiently handling multiple items simultaneously in industrial automation applications. It consists of 4 vacuum end-effectors, each capable of picking up items and placing them precisely at predefined locations independently. It features a compact ironless motor, enabling users to adjust the pitch of each axis to achieve the smallest gap possible. With its direct drive motor, it excels in delivering exceptional speed and acceleration, making it ideal for addressing high-speed pick and place motion challenges.

PZM-D Z-Axis Dynamic Miniature Actuator –

The dynamic miniature actuator is designed to precisely control motion along the vertical (Z-axis) direction with high accuracy in a compact, limited space. It offers high-precision positioning with sub-micron resolution and is capable of rapid and accurate motion. The PZM-D features an adjustable counter balance to accommodate different loads. It is suitable for various applications such as precision positioning systems, microscopy, semiconductor manufacturing, biomedical devices, and other fields where precise vertical motion control is required.

A plug-and-play compact module, the PLA Actuator is built with enhanced specifications for high-performance applications to improve productivity through uncompromised speed and precision. The key notable features of the PLA Actuator are compact size, high speed, high precision, and zero backlash, especially when compared to traditional actuators with ball screws. Bringing high accuracy and high repeatability to the applications the PLA Series is designed for – ranging from precision pick-and-place to automated optical inspection – the actuator is also a low-maintenance solution which is suitable for clean environment applications.

Consultation on PBA’s capabilities in Customised Precision Stages & Gantries

PBA’s expert team will be on hand to share information and insights on its core competence – the high-tech, in-demand customised precision stages & gantries. At the pinnacle of these solutions would be the Air Bearing Nano Precision Gantry – the industry’s top nano-grade precision gantry. This gantry is designed to provide ultra-smooth, dynamic motion performance with ultra-precise positioning accuracy for critical processes in automation. Suitable for cleanroom environments, the range of relevant semiconductor industry applications, for which superior precision is imperative, includes precision cutting, high-speed pick-and-place, high-accuracy inspection and more.

END

###

PBA Systems is an ISO-certified company and a member of the PBA Group. We are direct drive motion solutions experts for automation. We provide components, motors, system integration, and custom design services. Our advanced, High-Precision Direct Drive Technology improves the positioning, torque control, and efficiency of robotics systems, which are crucial in manufacturing automation. PBA Group specialises in proprietary robotics and automation technologies. Headquartered in Singapore; with advanced manufacturing and technology centres in Taiwan, Japan, Korea, Malaysia, Thailand and China; we have the capabilities of providing customised, swift motion solutions for global customers and system partners. For more information on PBA Systems, please visit www.pbasystems.com.sg/.

For PBA Systems Sales (Europe) Contact:

Mr. Sander Slagter

Technical Sales Manager

PBA Systems (NL) B.V.

Email: [email protected] / [email protected]

Tel: +(31) 85-7450026

For media queries, please contact:

PBA Group of Companies

T: +65 6576 6767