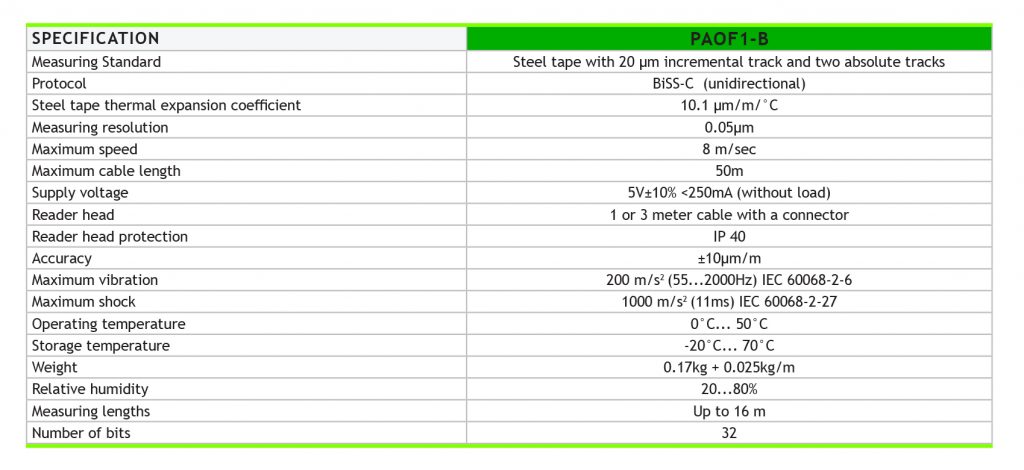

The absolute measurement system directly measures machine position digitally. The Absolute Linear Encoder possesses these key attributes: High-Speed and High Accuracy to deliver optimal performance. It also does not require homing of the machine.

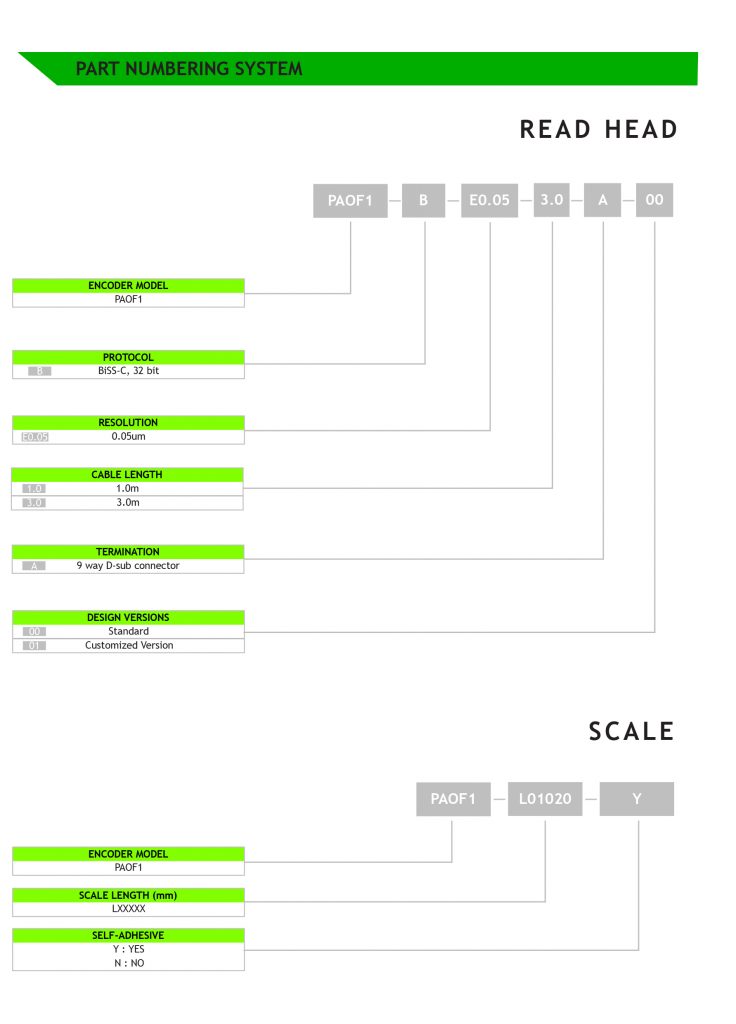

The system consists of a compact reader head. The PAOF Series Absolute Linear Encoder is built with the required electronic and optical components integrated into a single body that may be mounted from the side or from the top. The LED aids in mounting, and the system includes 1-meter or 3-metre cable with a connector, and a 10mm wide adhesive reflective stainless steel tape which is highly resistant to solvents.

Non-contact open absolute linear encoders features an auto-imaging principle which utilises diffused light reflected from the graduated steel tape. The reading system consists of an LED, as the light source of linear encoder; a specially-designed reticule that makes the image a monolithic photo detector element in the plane of the image.

For measurement, the Absolute Linear Encoder has two different etching methods:

- Incremental graduation: Used to generate incremental signals that are counted inside the reader head.

- Absolute graduation: A binary code designed with a special sequence which avoids repetition along the measuring length of the encoder.