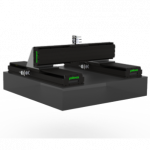

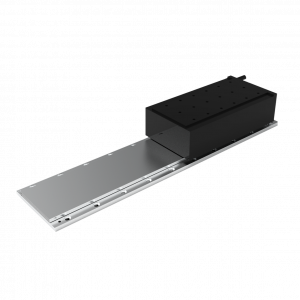

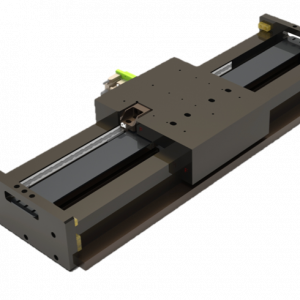

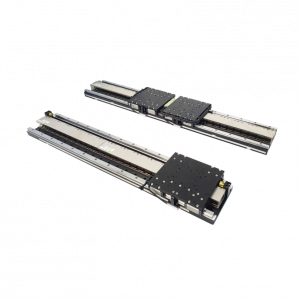

The PLA Actuator Series is built with enhanced specifications for high-performance production applications to improve productivity through uncompromised speed and precision. The key notable features of the PLA Actuator are compact size, high speed, high precision, and zero backlashes, especially when compared to traditional actuators with ball screws.

Bringing high accuracy and high repeatability to the applications the PLA Series is designed for – ranging from precision pick-and-place to automated optical inspection – the actuator is also a low-maintenance solution which is suitable for clean environment applications.

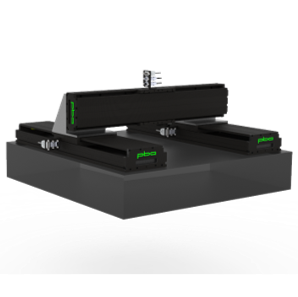

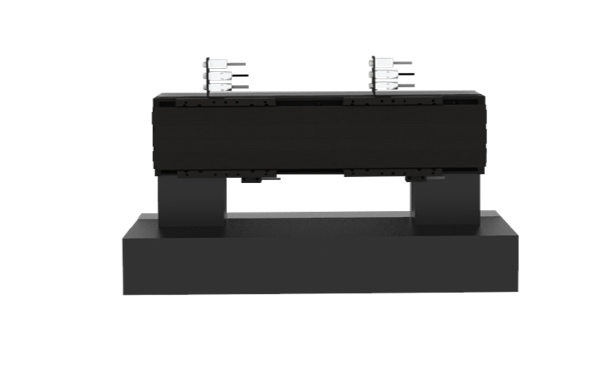

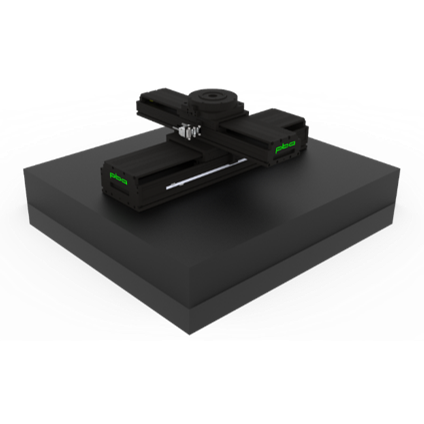

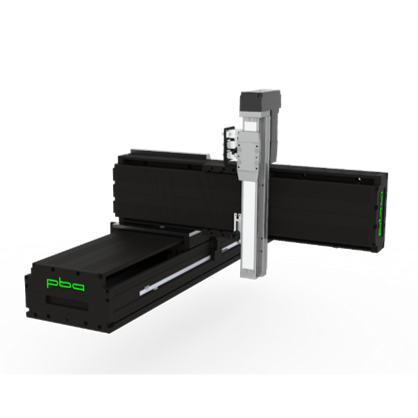

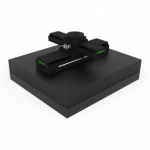

This precision-driven linear solution offers a modular actuator, including precision linear encoders and linear guideways. These modules offer optimal acceleration/velocity possibilities and rigidity that allows for faster settling, accuracy and highly repeatable positioning. The PLA actuator is configurable as an open frame system for basic applications as well as partially enclosed.

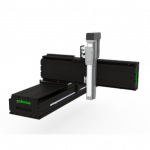

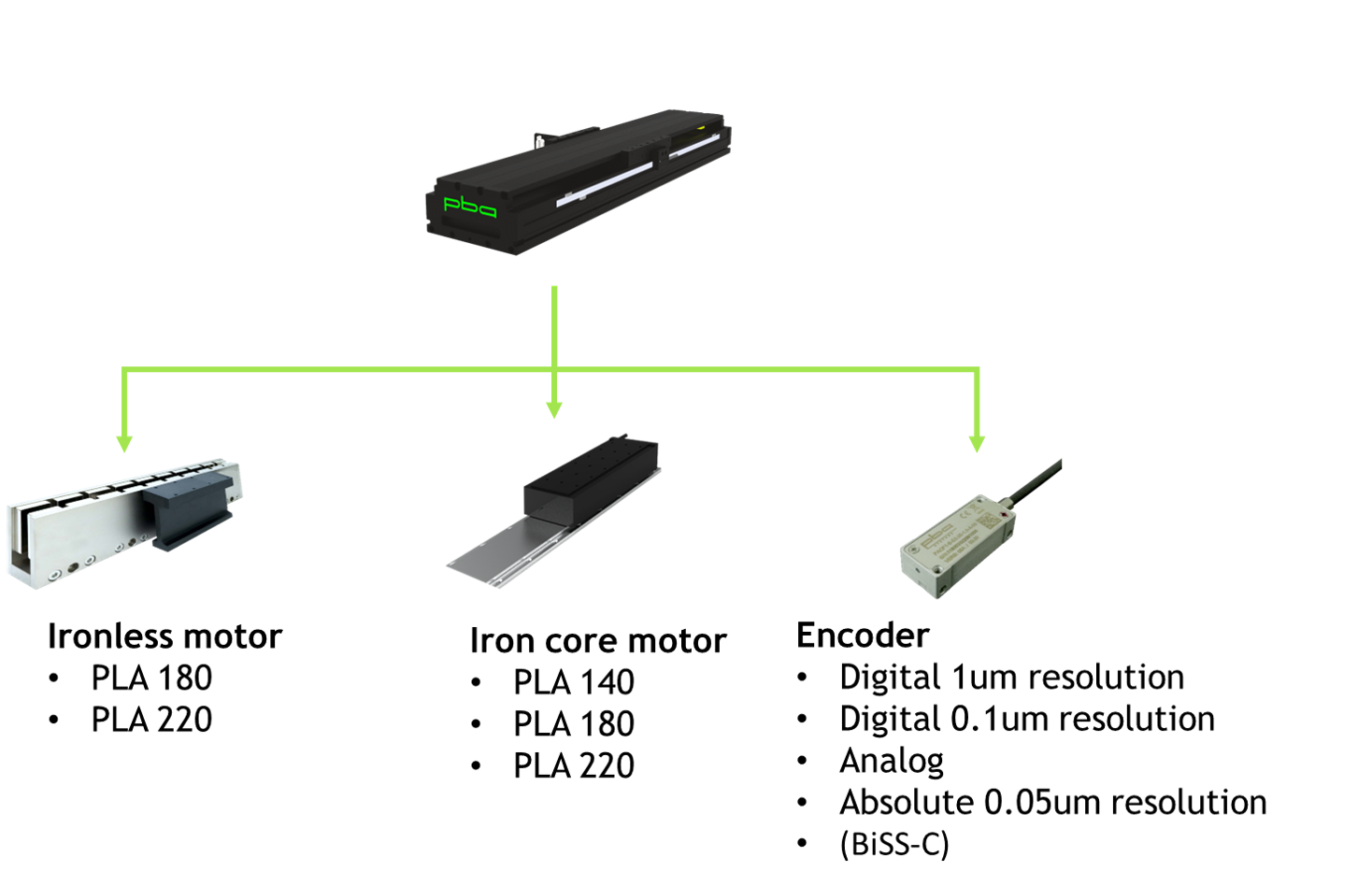

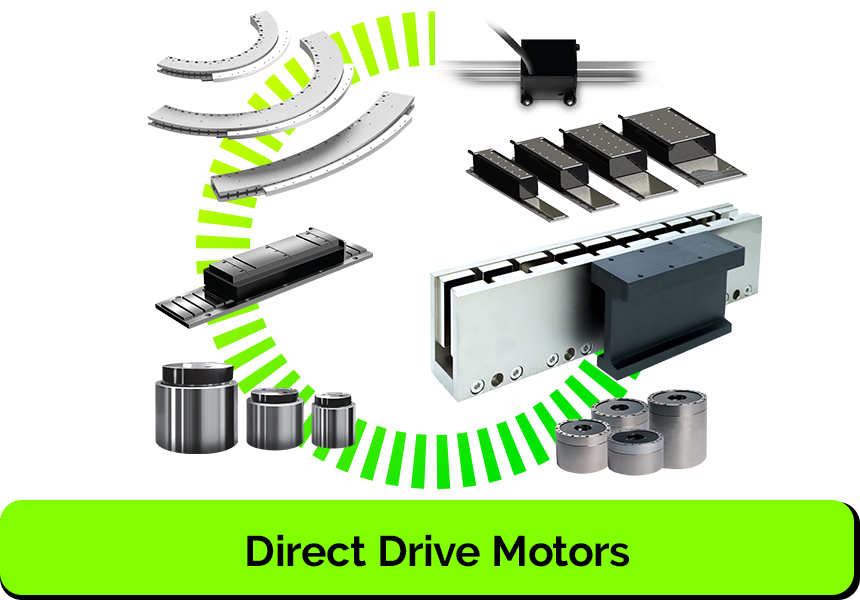

The PLA Series Linear Actuators come with a selection of either the DXF Ironless or the PIX Ironcore Linear Motors, two of our proprietary direct drive products, depending on each application and its required features.

|

High-Precision & High-Speed PLA Direct Drive Linear Actuators

|

Ball Screw Actuators

|

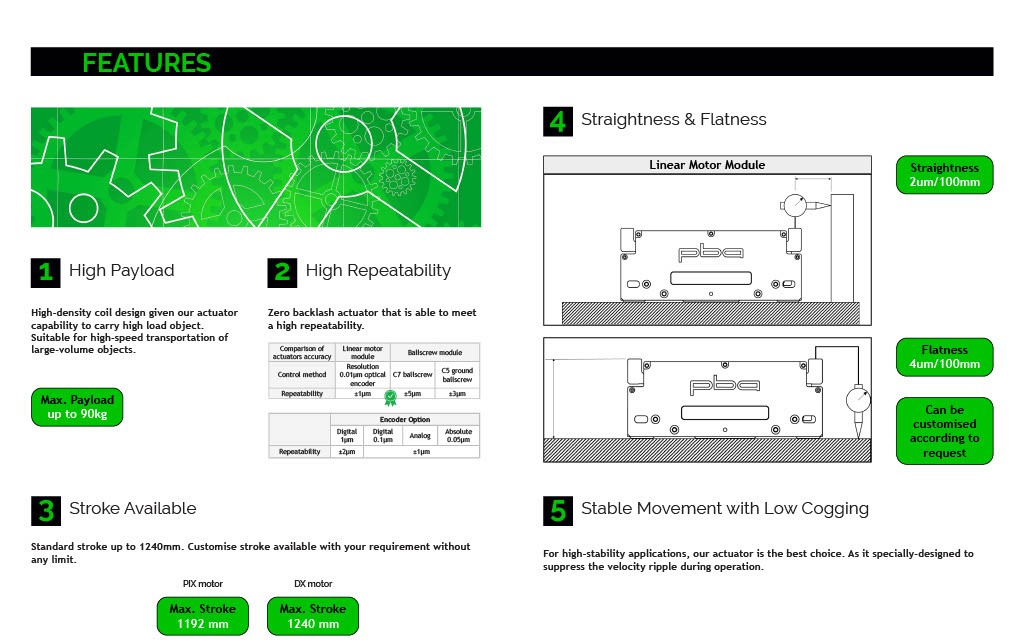

- Straightness: 10 µm/500mm

- Flatness: 20 µm/500mm

- Repeatability: ±1 µm

- Zero Backlash*

- Multiple carriages in a single-axis configuration

*Direct Drive attribute which results in better force transmission, as it reduces the number of components which would otherwise be used in a conventional ball screw actuator.

|

- Straightness: 50 µm

- Flatness: 50 µm/500mm

- Repeatability: ±50 µm

- Backlash due to multiple additional components (shaft, coupling and ballscrew)

|

KEY FEATURES & BENEFITS

SUPERIOR PERFORMANCE

When compared to conventional ball screw actuators, PLA Direct Drive Linear Actuators boast impactful & significant differences in performance – your machine will move faster and be more precise and accurate, resulting in maximised efficiency, throughput and productivity.

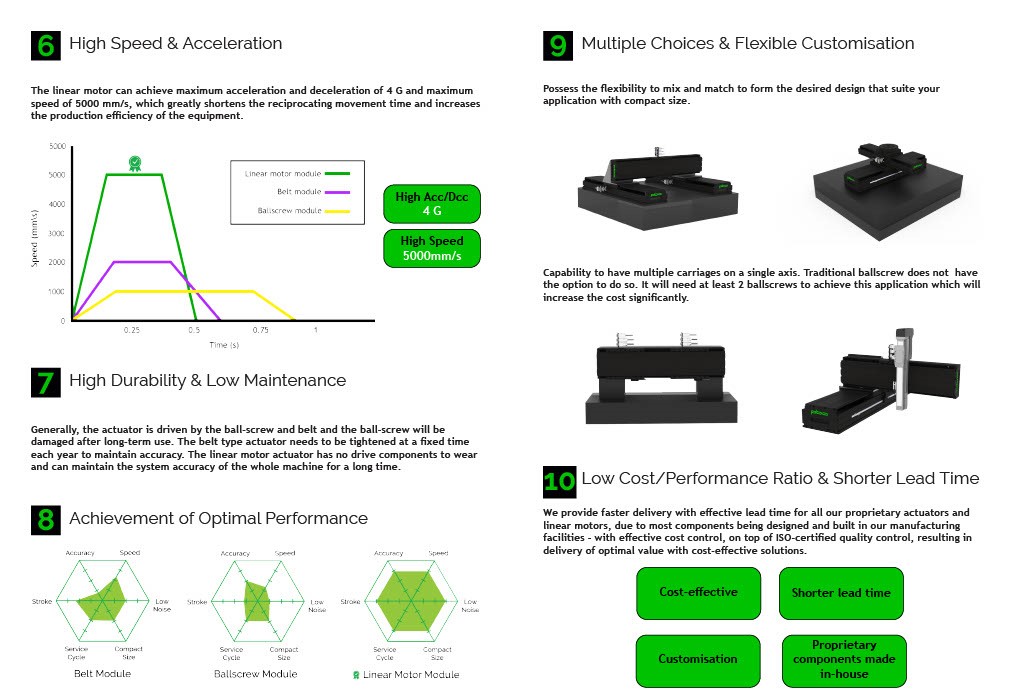

RELIABLE

Low-Maintenance and Durable (Long-Lasting) Compared to Ball Screws:

PLA linear actuators have low noise (friction) and high velocity vs ball screw actuators, which have high friction and are subject to wear-and-tear. Therefore, PLA is a more reliable, long-lasting investment which results in returns and cost-savings in the long-run.

IDEAL FOR CLEANROOM

A Solution Made for a Cleanroom Environment: PLA is a contactless linear motion solution, compared to ball screws which have friction resulting in particle generation.

UNLIMITED STROKES/CONFIGURABLE STROKES:

PLA is a linear motion solution made for long-stroke applications, compared to ball screw actuators which have limited range.

With a standard stroke of up to 1240mm and customised strokes over 3500mm, PLA can replace multiple ball screw actuators with one high-performing long-stroke actuator configuration.

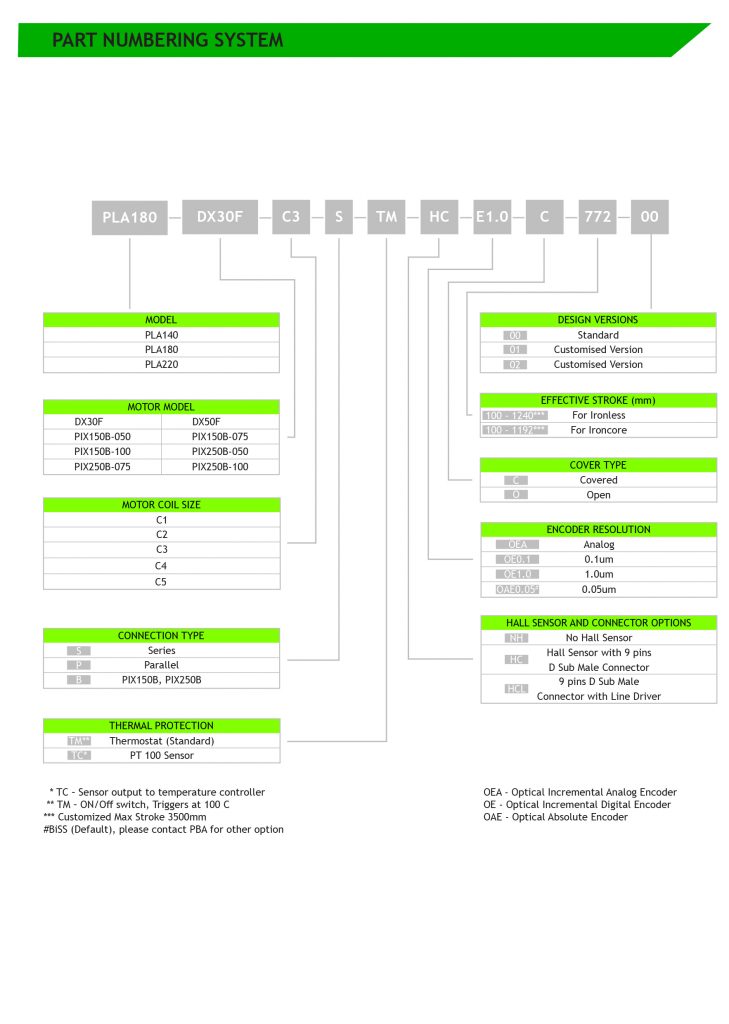

Specifications

Detailed specifications are available at the DOWNLOADS section of this site.

PLA Series – Specification table

| Model | Motor Series | Motor Coil | Effective Stroke (mm) | Continuous

Force (N) | Peak

Force (N) | Actuator Dimensions

W x H (mm) |

| PLA140 | Ironcore Linear Motor PIX150B | PIX150B-050-C2 | 100 - 1192

(In increment of 84mm) | 69 | 242 | 140 X 74 |

| PLA140 | Ironcore Linear Motor PIX150B | PIX150B-050-C3 | 101 - 1192

(In increment of 84mm) | 104 | 363 | 140 X 74 |

| PLA140 | Ironcore Linear Motor PIX150B | PIX150B-050-C4 | 102 - 1192

(In increment of 84mm) | 139 | 484 | 140 X 74 |

| PLA140 | Ironcore Linear Motor PIX250B | PIX250B-050-C1 | 100 - 1192

(In increment of 84mm) | 110 | 240 | 140 X 101 |

| PLA140 | Ironcore Linear Motor PIX250B | PIX250B-050-C2 | 101 - 1192

(In increment of 84mm) | 220 | 480 | 140 X 101 |

| PLA140 | Ironcore Linear Motor PIX250B | PIX250B-050-C3 | 102 - 1192

(In increment of 84mm) | 330 | 720 | 140 X 101 |

| PLA140 | Ironcore Linear Motor PIX250B | PIX250B-050-C4 | 103 - 1192

(In increment of 84mm) | 440 | 960 | 140 X 101 |

| PLA180 | Ironless Linear Motor DX30F | DX30F-C2 | 100 - 1240

(In increment of 60mm) | 69 | 347 | 180 X 81 |

| PLA180 | Ironless Linear Motor DX30F | DX30F-C3 | 101 - 1240

(In increment of 60mm) | 104 | 521 | 180 X 81 |

| PLA180 | Ironless Linear Motor DX30F | DX30F-C4 | 102 - 1240

(In increment of 60mm) | 139 | 695 | 180 X 81 |

| PLA180 | Ironless Linear Motor DX30F | DX30F-C5 | 103 - 1240

(In increment of 60mm) | 174 | 869 | 180 X 81 |

| PLA180 | Ironcore Linear Motor PIX150B | PIX150B-075-C2 | 100 - 1192

(In increment of 84mm) | 119 | 416 | 180 X 81 |

| PLA180 | Ironcore Linear Motor PIX150B | PIX150B-075-C3 | 101 - 1192

(In increment of 84mm) | 178 | 624 | 180 X 81 |

| PLA180 | Ironcore Linear Motor PIX150B | PIX150B-075-C4 | 102 - 1192

(In increment of 84mm) | 238 | 832 | 180 X 81 |

| PLA180 | Ironcore Linear Motor PIX250B | PIX250B-075-C2 | 103 - 1192

(In increment of 84mm) | 366 | 800 | 180 X 108 |

| PLA180 | Ironcore Linear Motor PIX250B | PIX250B-075-C3 | 104 - 1192

(In increment of 84mm) | 549 | 1200 | 180 X 108 |

| PLA180 | Ironcore Linear Motor PIX250B | PIX250B-075-C4 | 105 - 1192

(In increment of 84mm) | 733 | 1600 | 180 X 108 |

| PLA220 | Ironless Linear Motor DX50F | DX50F-C2 | 100 - 1240

(In increment of 60mm) | 128 | 638 | 225 X 91.7 |

| PLA220 | Ironless Linear Motor DX50F | DX50F-C3 | 101 - 1240

(In increment of 60mm) | 192 | 958 | 225 X 91.7 |

| PLA220 | Ironless Linear Motor DX50F | DX50F-C4 | 102 - 1240

(In increment of 60mm) | 255 | 1277 | 225 X 91.7 |

| PLA220 | Ironcore Linear Motor PIX150B | PIX150B-100-C2 | 97 - 1192

(In increment of 84mm) | 177 | 620 | 225 X 91.7 |

| PLA220 | Ironcore Linear Motor PIX150B | PIX150B-100-C3 | 98 - 1192

(In increment of 84mm) | 266 | 930 | 225 X 91.7 |

| PLA220 | Ironcore Linear Motor PIX150B | PIX150B-100-C4 | 99 - 1192

(In increment of 84mm) | 355 | 1240 | 225 X 91.7 |

| PLA220 | Ironcore Linear Motor PIX250B | PIX250B-100-C1 | 100 - 1192

(In increment of 84mm) | 274 | 600 | 225 X 105 |

| PLA220 | Ironcore Linear Motor PIX250B | PIX250B-100-C2 | 101 - 1192

(In increment of 84mm) | 548 | 1200 | 225 X 105 |

| PLA220 | Ironcore Linear Motor PIX250B | PIX250B-100-C3 | 102 - 1192

(In increment of 84mm) | 823 | 1800 | 225 X 105 |

| PLA220 | Ironcore Linear Motor PIX250B | PIX250B-100-C4 | 103 - 1192

(In increment of 84mm) | 1097 | 2400 | 225 X 105 |

Note: Continuous force is measured under natural convection, refer to the detailed parameters table for more information

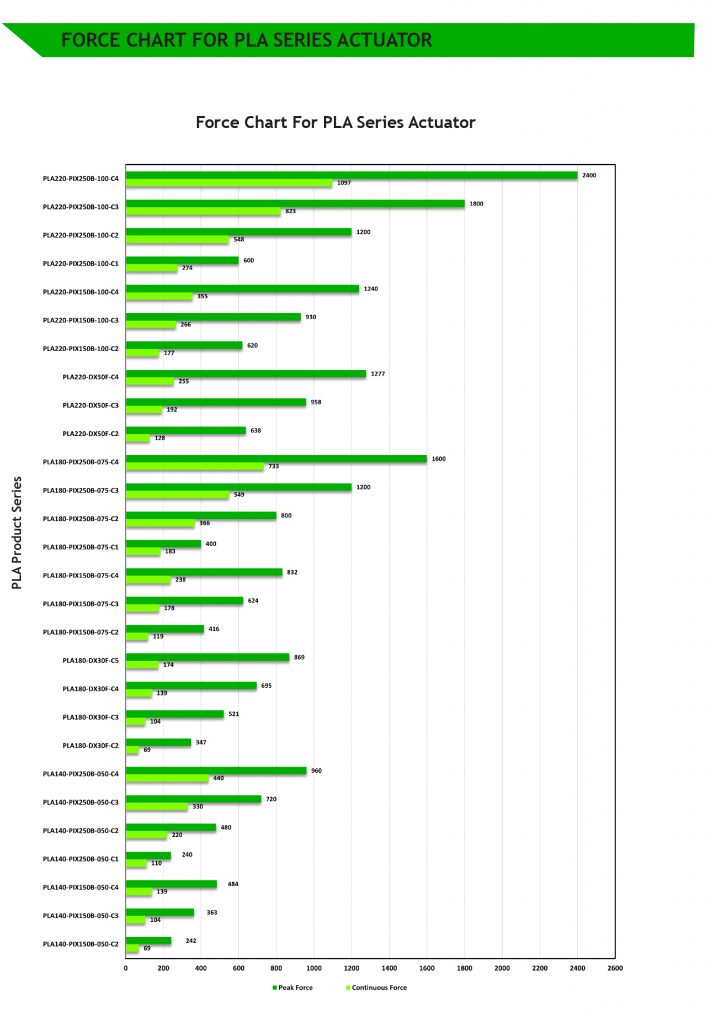

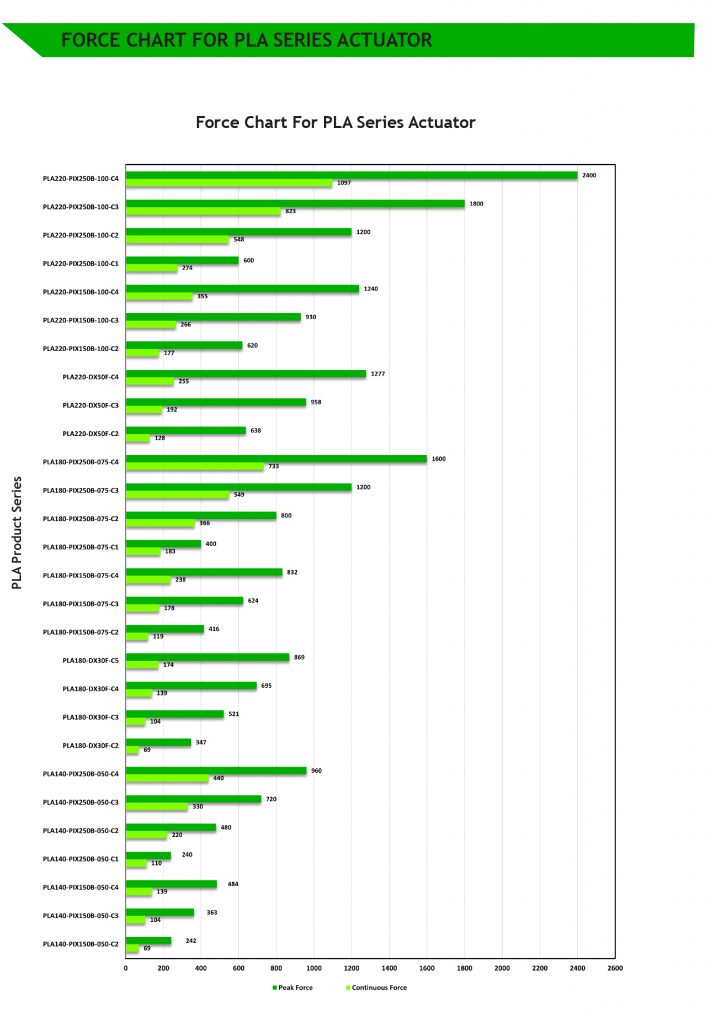

Force Chart for PLA Series

Please click on the chart image to view it in detail.

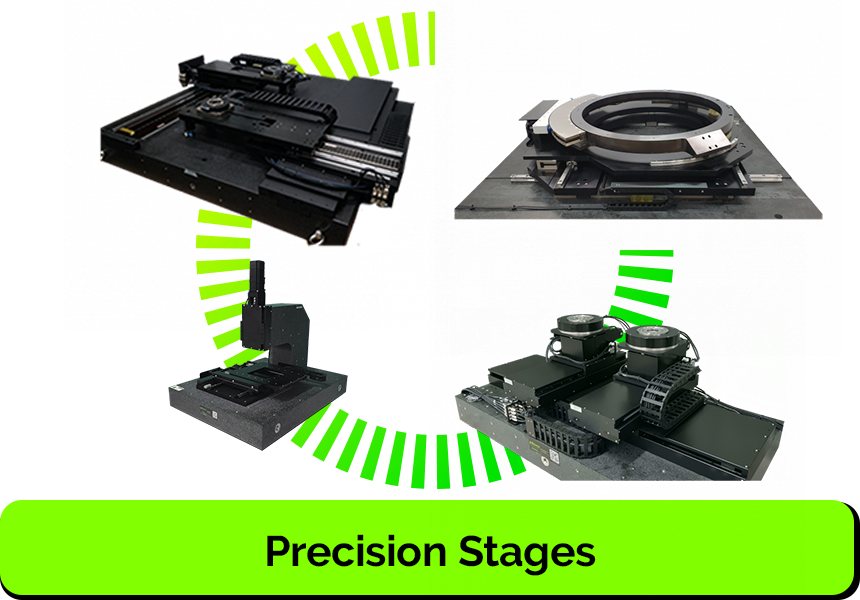

Applications

APPLICATIONS

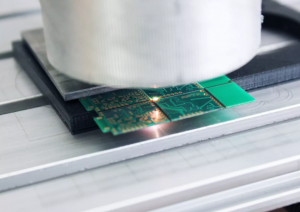

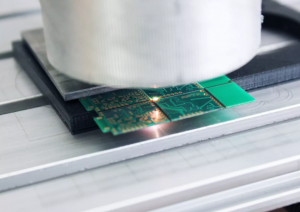

Laser Cutting Machine

Mount Laser Head onto the axes and move around XY axes to cut the PCB into pieces. Constant velocity is required for the process.

*Recommended Model: PLA180-DX30F & PLA220-DX50F

PCB Assembly Machine

Multiple components are being soldered to the PCB board, therefore a multiple carriage system mounted with an end effector can highly increase your productivity with a fast pace to insert the component into the PCB board for soldering.

*Recommended Model: PLA180-PIX & PLA220-PIX

Inspection Machine

Vision Inspection applications require high-stability movement for good image-capturing to prevent errors in inspection due to blurry images, especially in on-the-fly scanning processes.

*Recommended Model: PLA180-DX30F & PLA220-DX50F

Dispenser Machine

The dispensing process requires high accuracy and repeatability to ensure good distribution of precise microfluid. A zero backlash system is a must for this application. By mounting the dispenser head to the actuator and forming XY axes can provide a high-speed system with high accuracy and high-repeatability features.

*Recommended Model: PLA180-PIX & PLA220-PIX