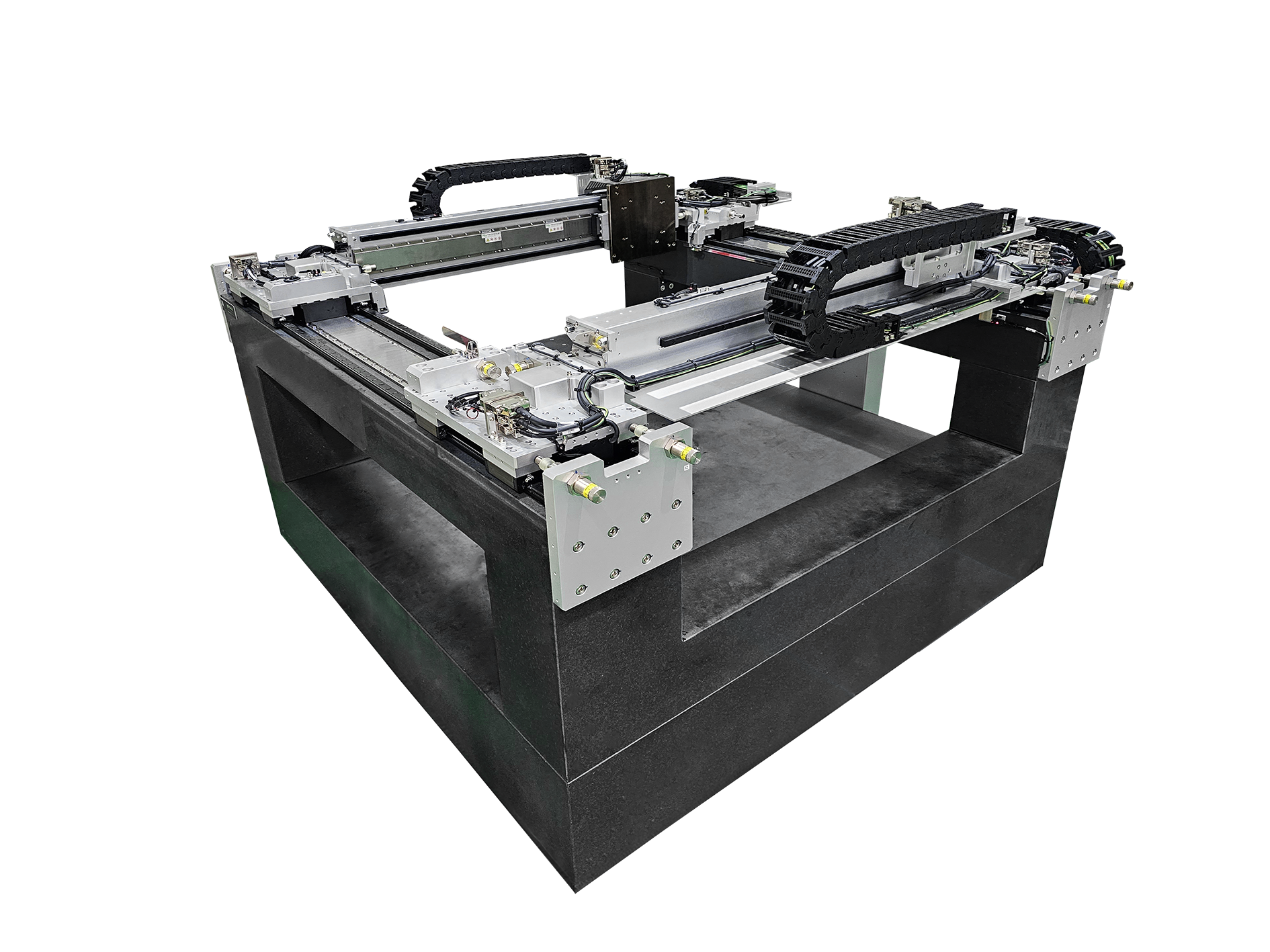

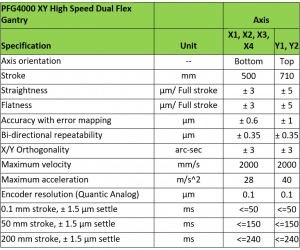

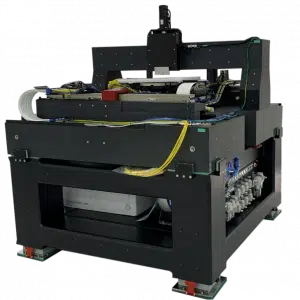

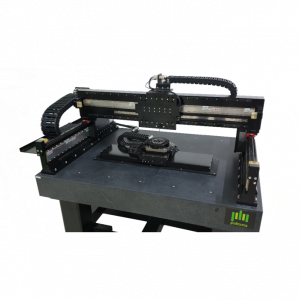

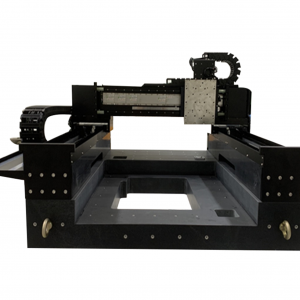

PBA’s Ultra-Precision XY Dual Gantry Motion System is a versatile multi-axis platform specially designed for semiconductor back-end manufacturing operations. It facilitates movement along 2 key axes – X & Y, effectively managing a total of 4 controlled axes.

Dual gantry systems can work in parallel, allowing for simultaneous processing of multiple workpieces or tasks, leading to higher throughput, and faster production rates, which are crucial in many manufacturing environments. Its innovative design is tailored to meet the most challenging demands of modern die bonding processes, including Flip-chip, µ-LED bonding, dispensing applications, and more.

Leveraging an innovative motion system architecture, XY Dual Gantry Motion System achieves an excellent performance in both accuracy and precision concurrently, which are ± 350nm for local placement accuracy and up to 8k UPH throughput for most of the die bonding processes.

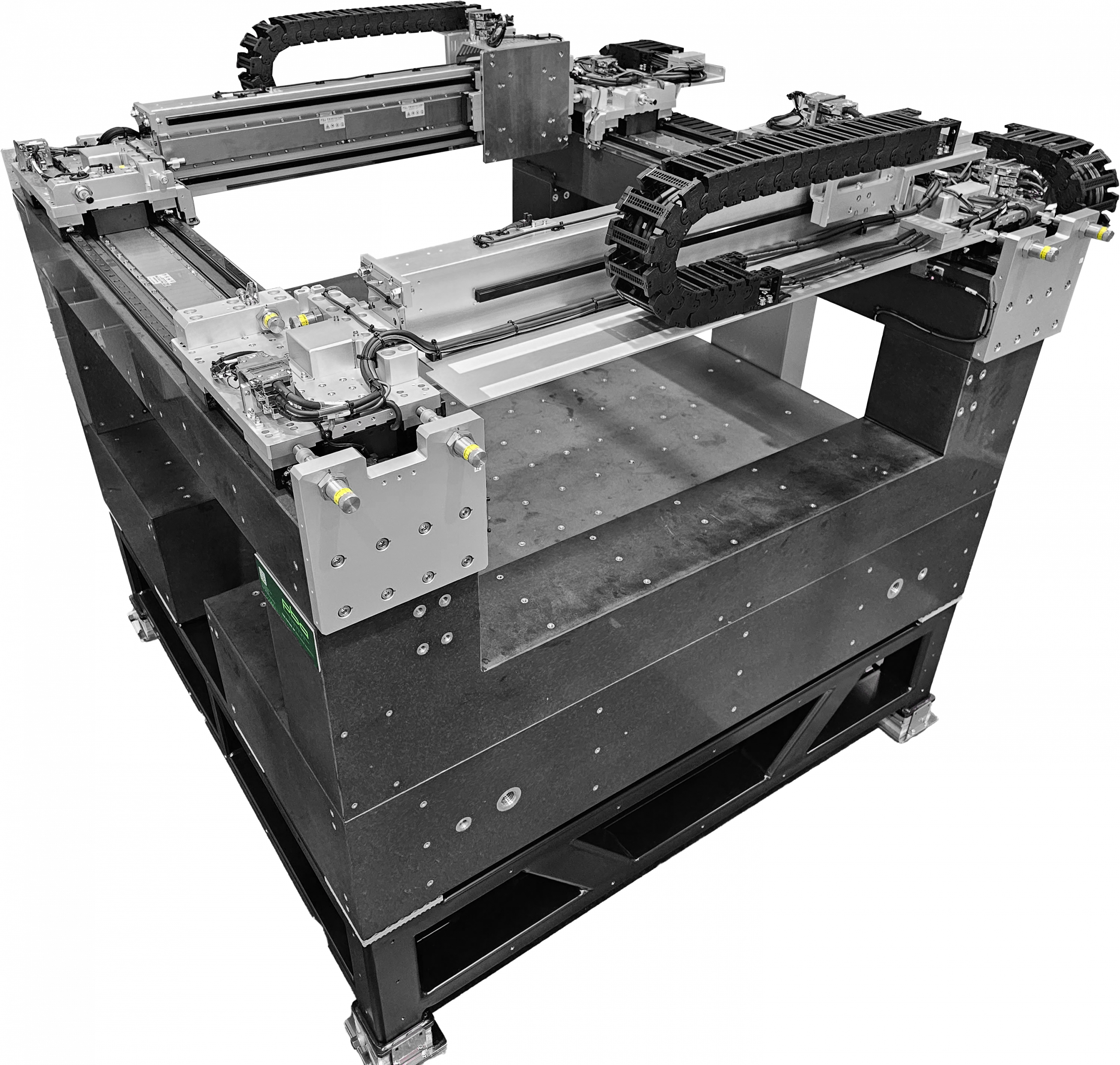

Features:

- Flex joint design

- ±350nm for local placement accuracy

- Max velocity up to 2 m/s

- Max acceleration up to 4G

- Controllable Thermal Expansion Technology

- Thermal Stability in 15 mins

- ISO 5 cleanroom compatible (Class 100)

- Controlled via advanced motion control system: Gantry control, Motion Boost & Multi-dimensional mapping.

Benefits:

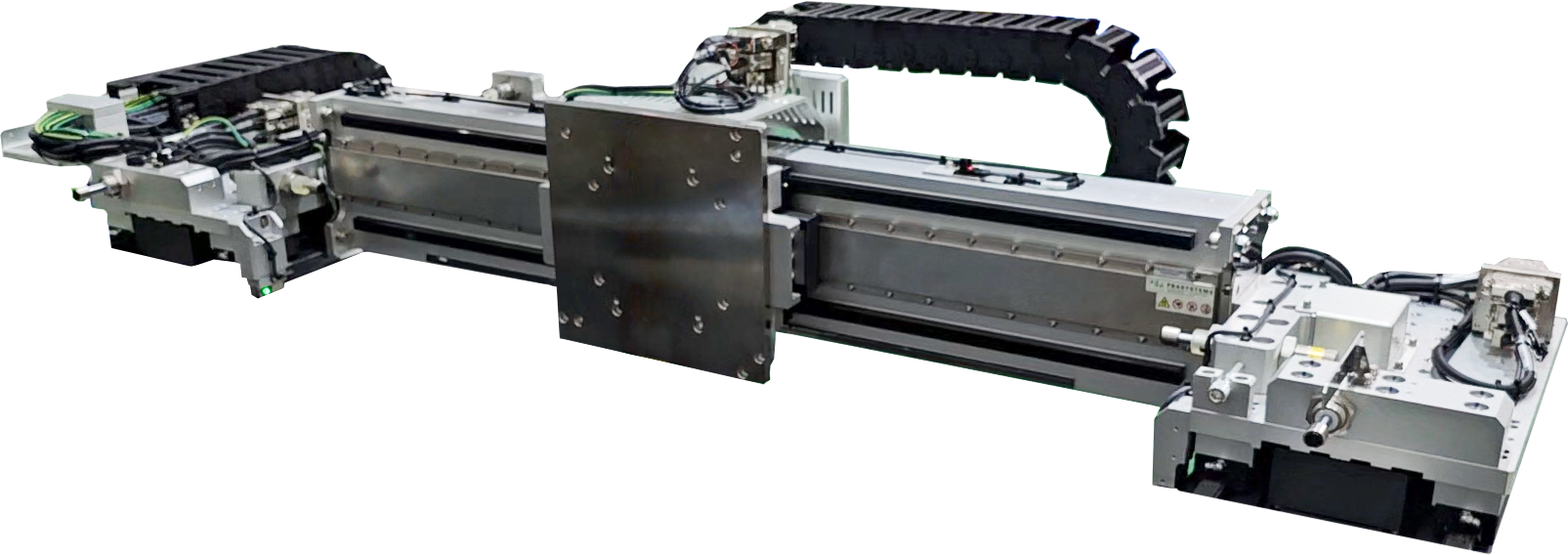

- Dual gantry design to support complex processes and motions.

- Maximizing throughput with high accuracy & high-speed design.

- Equipped with PBA Controllable Thermal Expansion Technology for heat insulation, it prevents thermal expansion that can lead to drops in accuracy.

- Boosting gantry performance with flex joint design.

- Dual gantry systems can often be more compact and flexible than having two separate systems. This can be particularly beneficial when floor space is limited.

- While the initial investment in a dual gantry system may be higher than a single-gantry or traditional system, the increased throughput, efficiency, and flexibility can lead to long-term cost savings.